Streamlining Warehouse Operations: The Advantages of the Electric Platform Hydraulic Lift

2025-06-09

Streamlining Warehouse Operations: The Advantages of the Electric Platform Hydraulic Lift

Introduction

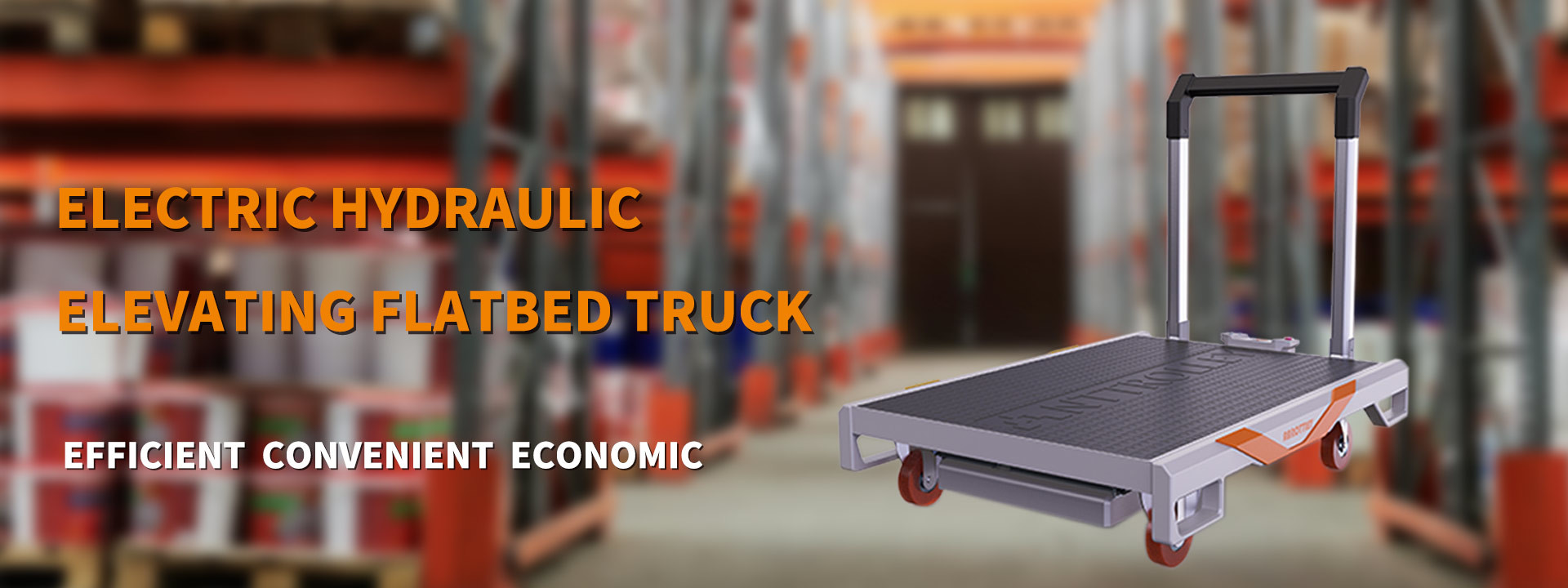

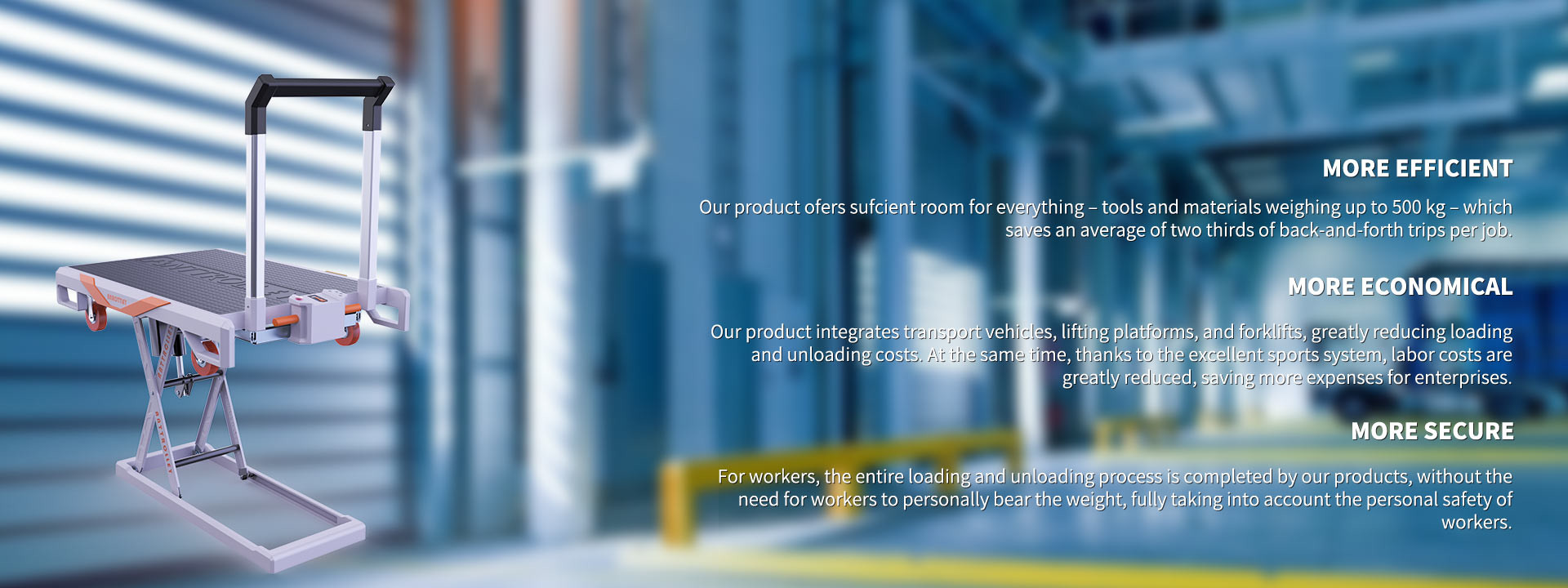

In fast-paced logistics and warehouse environments, efficiency is everything. Whether you're managing a warehouse, running a distribution center, or simply loading equipment into delivery vans, the need for safe and reliable material handling tools is critical. That’s where the Electric Platform Hydraulic Lift comes in—a game-changing solution that redefines how goods are lifted and transported.

What is an Electric Platform Hydraulic Lift?

An Electric Platform Hydraulic Lift is a powered lifting device equipped with a flat platform, scissor-lift mechanism, and mobility wheels. It’s designed to elevate, transport, and load heavy or bulky items with minimal effort. Powered electrically, it removes the strain of manual lifting and reduces injury risks significantly.

Key Features and Advantages

1. Electric-Powered Efficiency

Forget about hand-cranking or pumping. The electric lift mechanism allows users to raise or lower loads effortlessly with just the push of a button. This automation saves time and reduces operator fatigue.

2. Sturdy Scissor-Lift Design

The robust scissor-lift structure ensures stability under heavy loads. Whether it's oil drums or boxed diesel engines, the platform remains balanced and secure during operation.

3. High Load Capacity

Built to handle industrial-grade loads, this lift can support items like:

200L oil barrels

Boxed engines and tools

Heavy cartons or machinery parts

4. Easy Mobility

Equipped with industrial casters, the lift can be easily rolled across smooth factory or warehouse floors. The wheels are lockable to ensure safety during loading and unloading.

5. Versatile Applications

This lift is ideal for various use-cases, including:

Warehouse logistics

Factory production lines

Van and truck loading

Workshop equipment handling

Real-World Use Cases

Imagine trying to load two full 200L oil barrels into a delivery van by hand—it’s time-consuming and risky. With our electric platform lift, workers can simply roll the barrels onto the platform, elevate it to van height, and slide the load in seamlessly. It’s not just about convenience—it’s about safety and speed.

Similarly, when transporting boxed diesel engines (as shown in the product images), the platform lift allows for precise alignment with vehicle loading bays, eliminating the need for forklifts or hoists.

Boosting Productivity in the Workplace

By reducing the physical strain and manual labor involved in lifting, this tool helps companies:

Reduce workplace injuries

Speed up logistics processes

Minimize labor costs

Improve employee satisfaction

Compact Yet Powerful

Despite its industrial strength, the Electric Platform Hydraulic Lift has a compact footprint, making it easy to store or move when not in use. It fits into small warehouse spaces and narrow aisles, proving that big performance can come in small packages.

Who Should Use It?

This lift is ideal for:

Logistics and transport companies

Manufacturing plants

E-commerce fulfillment centers

Auto repair shops

Retail warehouses

If your business involves heavy lifting or frequent cargo transfers, this lift will quickly become your most trusted tool.

Conclusion

The Electric Platform Hydraulic Lift is more than just equipment—it’s a productivity partner. Designed with safety, efficiency, and versatility in mind, it’s perfect for anyone looking to modernize their material handling operations. Say goodbye to manual strain and hello to smooth, powered lifting!

Whether you're moving barrels, engines, or bulk-packed items, this lift makes it quicker, safer, and smarter. Upgrade your operations today and experience the difference.

View More

Maintenance Of Fixed Lifting Platform

2024-08-05

The elevator shall be inspected and maintained regularly, and hidden dangers shall be eliminated immediately to eliminate the faults as far as possible, which is beneficial to improving the working efficiency, equipment service life and ensuring the safety performance of the elevator.

At least twice a month, grease shall be added to the main transmission position of the machine equipped with grease fittings for lubrication. If it is found that the part cannot be filled with butter, the oil circuit must be dredged or the grease nozzle must be replaced until butter is filled, otherwise the platform is forbidden to use. Check the working condition of the pin shaft regularly every month. If the set screw of the pin shaft is loose, be sure to pin it tightly to prevent the pin shaft from falling off and causing accidents.

When maintaining and cleaning the elevator, be sure to support the safety brace. Do not load or unload goods while working to avoid impact on the elevator and damage to mechanical equipment.

View More

Enhance Your Business Efficiency And Safety: 350KG Manual Hydraulic Scissor Lift Trolley For Cargo Platform And Truck Platform

2024-08-05

In the modern logistics and warehousing industry, it is crucial to improve work efficiency and reduce labor intensity. Manual hydraulic scissor lift cargo platform truck platform carts, as an efficient lifting device, can effectively solve the problem of cargo handling and lifting. ZOHO has been committed to providing high-quality logistics solutions to meet the needs of our customers for speed, efficiency, and safety. Today, we would like to introduce you to our latest product – a 350kg Manual Hydraulic Scissor Lift Platform Trolley.

350kg Manual Hydraulic Scissor Lift Performance

Load capacity: can carry a maximum weight of 350kg, suitable for medium load handling needs.

Hydraulic system: adopts hydraulic lifting system, simple and easy to operate, providing a stable lifting process.

Scissor mechanism: Adopting the design of the scissor mechanism, it has good stability and carrying capacity, and can ensure the goods in the lifting and lowering process smoothly without vibration.

Lifting Height: The provided lifting height is moderate, which can meet the lifting needs in most of the storage and logistics scenarios.

Stable structure: The overall structure is stable and durable, made of high-quality steel, with good durability and stability.

Safety: Equipped with safety limit devices and anti-slip surfaces to ensure the safety of operators and prevent goods from sliding during transportation.

Usage Of 350KG Manual Hydraulic Scissor Lift Trolley Made By ANTTROLLEY

Adjusting the height: Firstly, place the goods on the lifting platform and then adjust the lifting platform to the required height by the handle.

Fixing the goods: After the lifting platform has been adjusted to the appropriate height, make sure the goods are firmly placed on the platform and use straps or clamps to fix them.

Operate the lift: Turn the handle to the lift position, and start the hydraulic system, the lifting platform will start to slowly rise or fall until it reaches the desired height or position.

Carrying goods: After the lifting platform reaches the target height, carry the goods from the platform to the destination to complete the handling task.

Close the hydraulic system: After completing the lifting task, turn the handle back to the original position and close the hydraulic system to ensure safe use.

Superior Performance About 350KG Cargo Platform Trolley

ANTTROLLEY’s 350kg Manual Hydraulic Scissor Lift Platform Truck utilizes an advanced hydraulic system to easily lift heavy loads to 350kg. Its solid scissor construction ensures stability and safety during the lifting process. Whether it is used in warehouses, factories, or freight vehicles, it can handle any scenario with ease!

ANTTROLLEY Manual Hydraulic Scissor Lift Trolley Provides Safe and Reliable

ANTTROLLEY has always prioritized the safety of our customers. That’s why our lift platform trucks are equipped with several safety devices, including non-slip surfaces, handle locking devices, and overload protection systems. No matter what environment you use it in, you can rest assured that your work will be done and remain safe.

Manual Hydraulic Scissor Lift Platform Truck Presents Flexible And Versatile

This manual hydraulic scissor lift platform truck is not only suitable for commercial and industrial use but can also be used in homes, offices, and warehouses. It can help you move goods, adjust the height of equipment, speed up the loading and unloading process, and improve work efficiency.

Commitment To Meeting Customer Needs

ANTTROLLEY has always been committed to provide high-quality logistics solutions to our customers. Our manual hydraulic scissor lift platform truck is not only an outstanding product but also a reflection of our commitment to our customers. We will continue to work hard and innovate to provide better services and products to our customers.

Whether you are in a warehouse, factory, or daily life, ANTTROLLEY’s manual hydraulic scissor lift platform truck is your indispensable partner. Its excellent performance, easy-to-use operation, and safe and reliable design will bring more convenience and efficiency to your work. Choose ANTTROLLEY, choose high-quality logistics solutions, and let’s improve business efficiency and safety standards together!

View More

Safety Rules For Maintenance Of Electric Stacker

2024-08-05

(1) Keep the maintenance site clean and sanitary.

(2) Do not carry loose items or valuables with you during maintenance.

Be careful!

When repairing the electrical system of the electric stacker, if the metal contacts the energized electronic components, it is easy to cause short circuit or combustion. So please take off your watch, earrings or other accessories.

(3) Unplug the power socket and disconnect the power before the maintenance of the electric stacker.

(4) Turn off the key switch of the forklift before opening the left and right box covers or the electrical system.

(5) Before checking the hydraulic system, lower the fork to release the system pressure.

(6) When checking the oil leakage of the car body, please wipe it with paper or cardboard and do not touch it directly with your hands. Avoid scalding.

(7) Please note that the oil temperature in the transmission device or hydraulic system may be high. The electric stacker should be cooled first, and then the gear oil or hydraulic oil should be replaced to prevent burning due to high oil temperature.

(8) The hydraulic system should be filled with new clean oil.

Be careful!

If the hydraulic oil is not clean, it will affect the precision hydraulic components and reduce the capacity of the entire hydraulic system.

If different brands of hydraulic oil are used, it will damage the hydraulic components and affect the system capacity. Therefore, when adding or replacing hydraulic fluid, pay attention to the use of uniform brand.

(9) Please comply with relevant laws and regulations, protect the environment, store and discharge oil according to regulations, and do not discharge it to the sewer.

(10) When welding the car body, disconnect the battery power supply. Because the welding current may enter the battery during welding, please cut off the battery in order to avoid this situation.

(11) When working under the electric stacker, the electric stacker shall be firmly supported by the bracket.

Warning!

Improper support will cause the electric stacker to tip over and hurt people. If the electric stacker is not protected by lifting equipment or support, it is forbidden to work under the electric stacker.

View More